Real-time Report Function Introduction

Through the PC management backend, you can view the real-time production status of machines.

View Real-time Production Reports

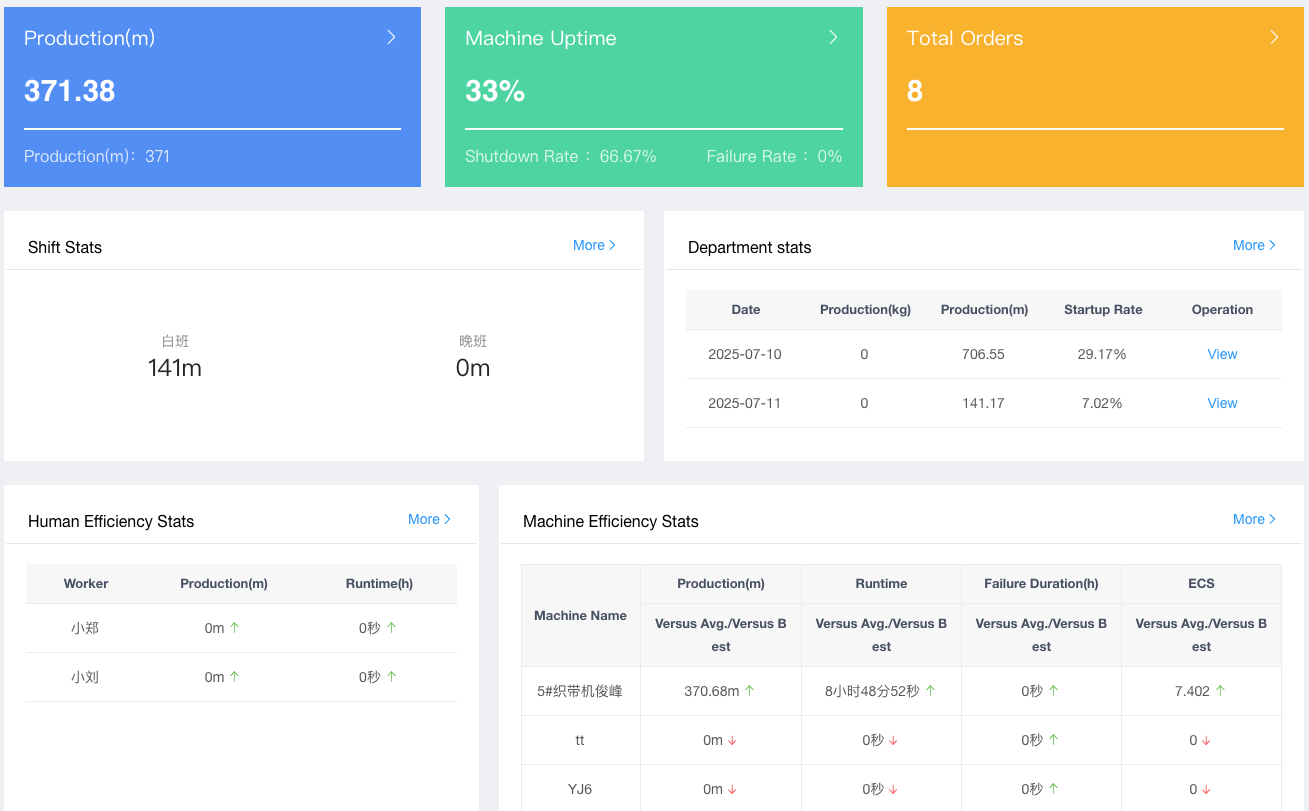

Home Dashboard

In the PC management backend, click on the homepage to see the following interface:

This is a real-time data report that includes today's total output, machine uptime rate, order production status, output of each shift, output of recent days, employee productivity ranking for today, and machine productivity ranking for today.

Equipment Monitoring

Click on Statistics -> Equipment Monitoring to view the equipment monitoring page.

The top part of the figure lists the total number of machines currently installed with counters, the number of machines in operation, the number of machines in fault (broken yarn), and the number of machines stopped.

Below the equipment list, each square represents a machine, with different colors indicating different statuses:

- Gray: Equipment is not powered on.

- Green: Equipment is running.

- Orange: Equipment is in fault (broken yarn).

The information displayed in the equipment squares includes:

- Equipment name: You can modify the equipment name in the equipment management. It is recommended to name it according to the actual position of the machine, such as row + column.

- Output of the current shift, in meters or kilograms. To switch between displaying meters or kilograms, go to Factory Management -> Company Settings - Main Display Indicator.

- Current clock-in status of the equipment: If the equipment is running but not clocked in, there will be a red "Not Clocked In" label. If clocked in, it displays the name of the employee who clocked in today.

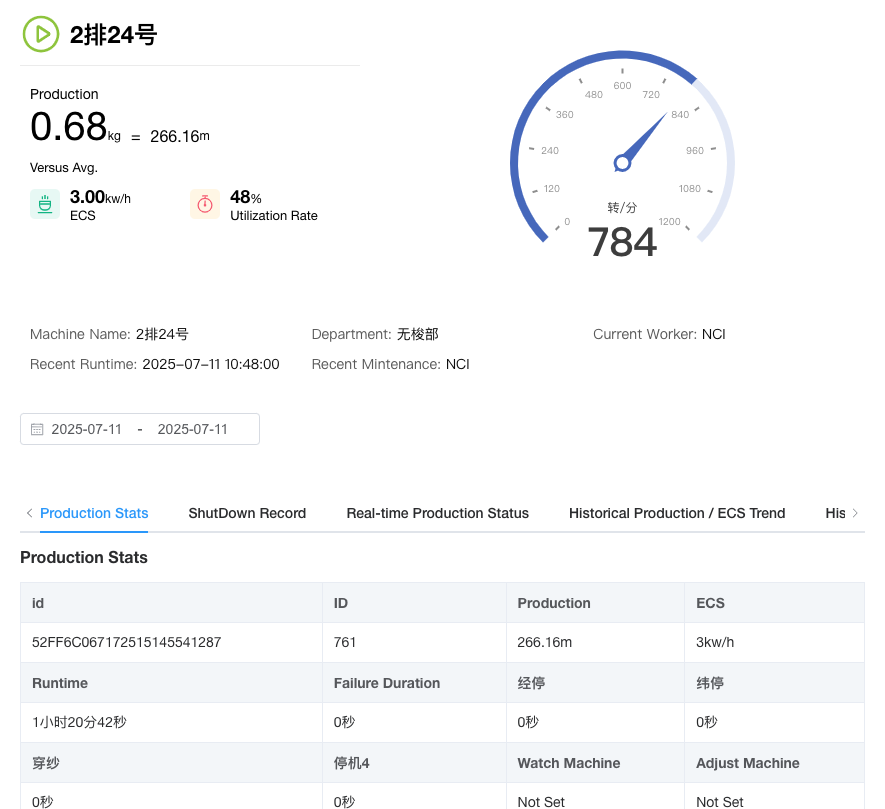

Equipment Details

Click on the equipment square to view detailed information about the equipment.

Here, you can see the current operating speed, output, running time, and utilization rate of the machine.

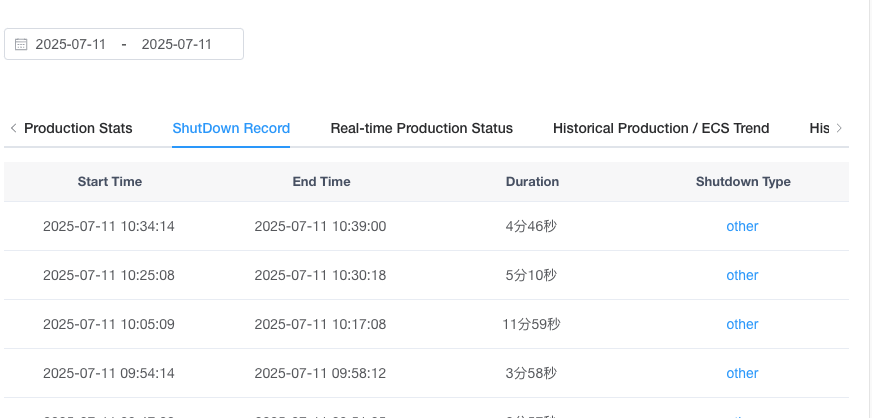

Downtime Records

Click on the Downtime Records tab to view the downtime records of the equipment.

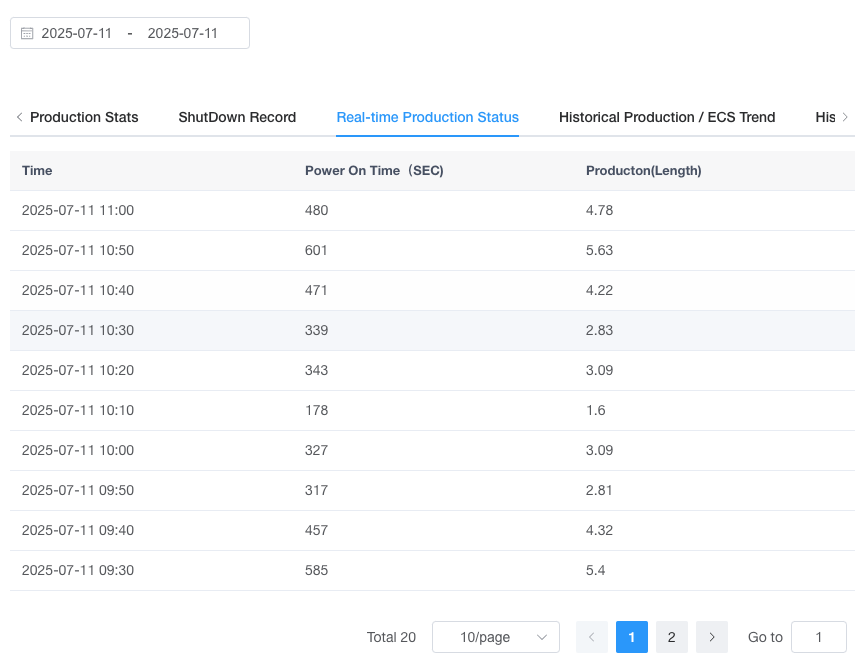

Real-time Production Records

Click on the Real-time Production Records tab to view the real-time production records of the equipment. The production records here are calculated based on one strip and multiplied by the stretch ratio set in the order. If no stretch ratio has been set, the default value is 1.